PREMIUM ABRASIVES FOR EVERY INDUSTRY

Rust Removal, Surface Cleaning, Paint Stripping, and More

Airo Shot Blast specializes not only in advanced blasting machines but also in providing high-quality abrasive media that ensures precise, efficient, and cost-effective surface preparation. Abrasive media plays a crucial role in achieving the desired finish, cleaning, and surface texture for various industrial applications. Whether it’s rust removal, paint stripping, deburring, or polishing, the right abrasive media determines the quality of the final output.

We offer a wide range of abrasive materials that are carefully processed to meet international standards. Our abrasives are suitable for different blasting methods, including sand blasting, shot blasting, grit blasting, and air operated blasting.

What is Abrasive Media?

Abrasive media refers to granular materials used in blasting machines to clean, smooth, or shape surfaces. These materials vary in hardness, density, and size, making them suitable for different applications. Depending on the job requirements, abrasive media can be metallic or non-metallic, natural or synthetic.

- By striking the surface with controlled pressure, abrasives help:

-

- Remove unwanted contaminants (rust, scale, paint, grease).

-

- Prepare surfaces for painting, coating, or welding.

-

- Enhance adhesion by creating the right surface profile.

-

- Improve durability and extend the life of materials.

Types of Abrasive Media Offered by Airo Shot Blast

We supply a complete range of abrasive blasting media designed to suit all industries:

1. Steel Shots

-

Made from high-quality carbon steel.

-

Spherical in shape, ideal for peening and cleaning metal surfaces.

-

Reusable multiple times, making them cost-effective.

-

Commonly used in automotive, aerospace, and foundry industries.

2. Steel Grit

-

Angular in shape for aggressive cleaning and surface profiling.

-

Provides a sharper finish compared to steel shots.

-

Perfect for removing rust, scale, and old coatings.

-

Ideal for heavy-duty blasting on steel structures and ships.

-

Hard and sharp abrasive.

-

Excellent for precise etching and surface finishing.

-

Suitable for non-ferrous metals, stainless steel, and glass etching.

-

Long-lasting and reusable.

4. Garnet Sand

-

Natural mineral abrasive, eco-friendly.

-

Delivers fast cutting and low dust emission.

-

Perfect for water jet cutting, surface cleaning, and sand blasting.

-

Non-toxic and recyclable.

5. Glass Beads

-

Round, smooth, and lightweight abrasive.

-

Provides a satin or matte finish without damaging surfaces.

-

Commonly used in aerospace, automotive, and medical equipment cleaning.

-

Ideal for polishing and peening.

6. Copper Slag

-

By-product of copper smelting, cost-effective.

-

Angular shape, ideal for removing thick coatings, rust, and scale.

-

Suitable for open blasting applications.

-

Environmentally friendly alternative to silica sand.

7. Quartz Sand / Silica Sand

-

Traditional abrasive media.

-

Effective for general cleaning and surface preparation.

-

Not recommended in enclosed blasting due to dust hazards.

Airo Shot Blast – Trusted Partner in Abrasive Media

With over a decade of expertise, Airo Shot Blast has built a reputation as a trusted manufacturer and supplier of blasting solutions. Our abrasive media is designed to maximize machine efficiency, reduce operational costs, and deliver superior surface results.

Whether you need bulk supply for industrial projects or custom solutions, we ensure timely delivery and premium quality at competitive prices.

Choosing the right abrasive media is as important as selecting the right blasting machine. At Airo Shot Blast, we deliver both – world-class blasting equipment and premium abrasives tailored for every application. With our wide range of media and expert support, you can achieve perfect surface finishes, improved productivity, and cost savings.

👉 Contact Airo Shot Blast today to get the best abrasive media solutions in India for your industrial needs.

Features of Abrasive Media

- High Quality & Durability – Processed under strict quality standards to ensure long-lasting performance.

- Wide Range – From steel shots to eco-friendly garnet, we offer abrasives for every application.

- Cost-Effective – Reusable media reduces operational costs.

- Eco-Friendly Options – Garnet, glass beads, and copper slag minimize environmental impact.

- Expert Guidance – Our technical team helps you select the right abrasive media for your needs.

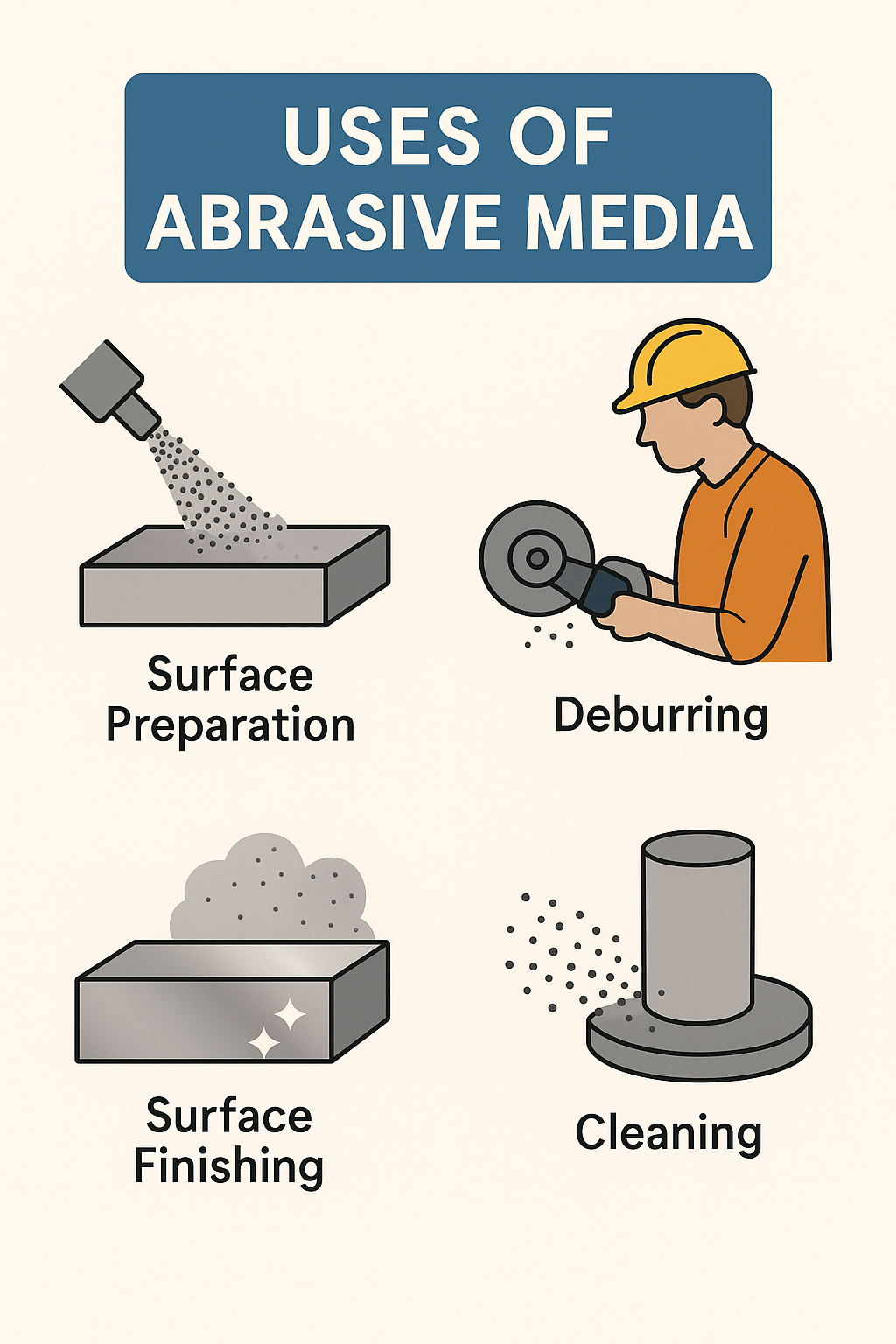

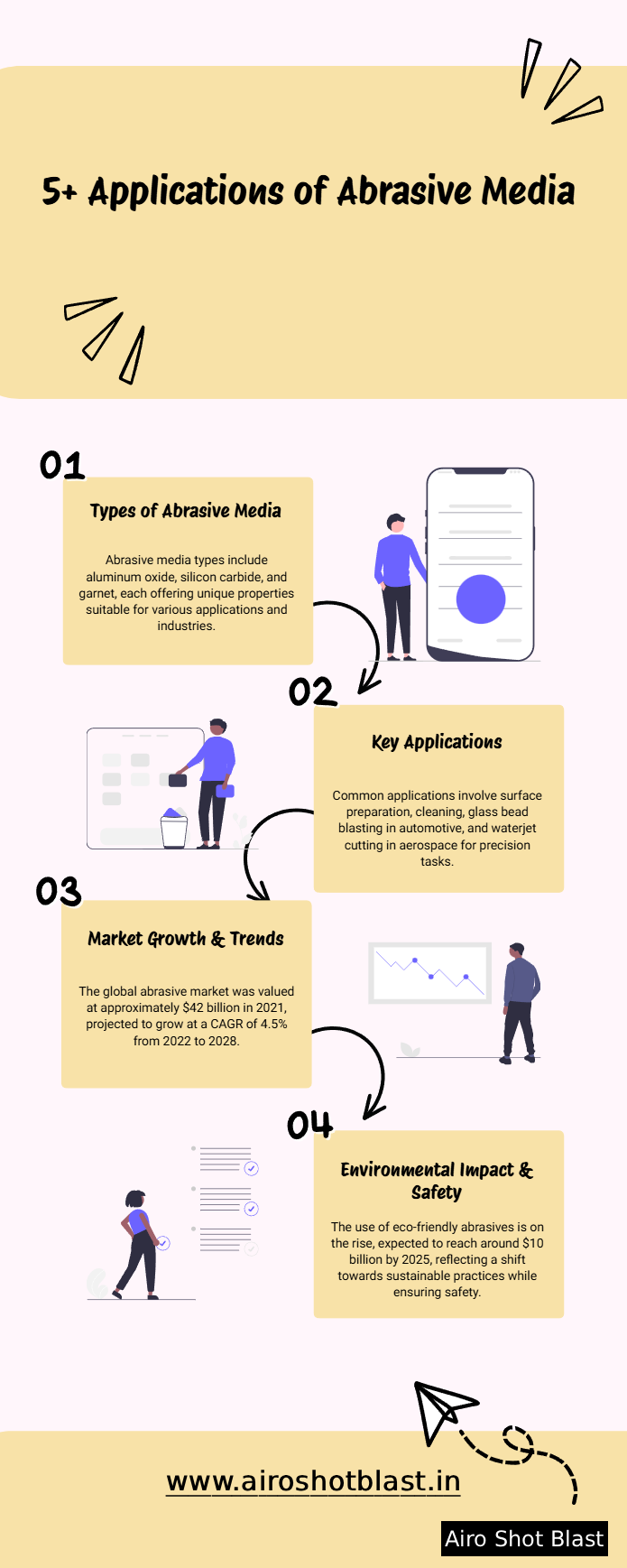

5+ Applications of Abrasive Media

Abrasive media from Airo Shot Blast is widely used across multiple industries:

-

1. Surface Cleaning: Removal of rust, mill scale, old paint, and grease.

-

2. Surface Preparation: Creating proper anchor profiles for coatings, paint, or galvanizing.

-

3. Peening: Enhancing the fatigue strength of metal components.

-

4. Deburring & Finishing: Smoothing sharp edges and polishing surfaces.

-

5. Etching & Texturing: Used in glass, stone, and stainless steel etching.

-

6. Industrial Maintenance: Cleaning pipelines, tanks, bridges, and heavy machinery.

Abrasive Media Specifications

| Media Type | Shape | Hardness (Mohs) | Applications | Reusability |

|---|---|---|---|---|

| Steel Shots | Spherical | 40 – 50 HRC | Peening, cleaning, surface prep | High |

| Steel Grit | Angular | 50 – 60 HRC | Rust & coating removal, profiling | High |

| Aluminium Oxide | Angular | 9 Mohs | Precision etching, polishing | High |

| Garnet | Angular | 7.5 – 8 Mohs | Cutting, blasting, eco-friendly use | Medium |

| Glass Beads | Round | 5 – 6 Mohs | Polishing, satin finishing | Medium |

| Copper Slag | Angular | 6 – 7 Mohs | Heavy-duty coating removal | Low-Medium |

Get In Touch

📍 P.No. 324-25, 378-79-80, Khasra No. 9/4, Shree Yade Gaun, Near Banar Ring Road, Jodhpur (Rajasthan) - 342027

📧 info@airoshotblast.in

Website

Call Us On

📞 +91 9119207701