FREQUANTLY ASK QUESTIONS

Do You Have for Any Questions?

Curious about shot blasting machines and their applications? Explore our detailed guide FAQ - Airo Shot Blast Equipments. Get clear, practical answers about features, uses, maintenance, and buying tips for the best industrial blasting equipment.

Ultimate Guide to Industrial Surface Solutions

When it comes to heavy-duty surface preparation, you can’t ignore shot blasting machines. From cleaning corroded steel structures to preparing surfaces for coatings, these machines are game changers. And guess what? Airo Shot Blast Equipments is one of the big names in this industry, offering innovative and reliable blasting solutions worldwide.

But here’s the thing—whether you’re a first-time buyer, a seasoned plant manager, or just someone curious about blasting technology, you probably have a lot of questions. That’s exactly why we’ve put together this FAQ - Airo Shot Blast Equipments guide.

Think of this as your “one-stop shop” for answers. We’ll break down the technical jargon, clear up the confusion, and help you understand everything from machine types to safety tips—without the boring textbook vibes. Ready? Let’s dive right in!

Quick FAQs About Airo Shot Blast Equipments

1. Do Airo machines come with warranties?

Yes, most machines are covered under manufacturer warranties, usually ranging from 12–18 months.

2. Can I buy spares easily?

Definitely. Airo supplies spare parts and consumables to keep your machines running smoothly.

3. Are operators required to have training?

Yes, basic training is highly recommended. Airo also offers guidance to new buyers.

4. What’s the delivery time for machines?

Standard models are usually ready within a few weeks, while custom orders may take longer.

5. Can small businesses afford Airo machines?

Of course! With the portable P7 series, even small workshops can benefit from industrial-grade blasting.

FAQS - Airo Shot Blast Equipments

Shot blasting is an surface cleaning and finishing process that uses a stream of high-velocity steel shots, grits, or abrasives to clean or modify the surface of a material. It’s widely used in industries like construction, shipbuilding, automotive, aerospace, and more.

Here’s why it matters:

-

Rust removal: Wipes out rust and corrosion like magic.

-

Surface prep: Provides a strong base for paint, coatings, or galvanizing.

-

Strength enhancement: Improves fatigue resistance through shot peening.

-

Eco-friendly process: Recycles abrasive material, cutting down waste.

Without shot blasting, many industries would struggle with coating failures, weaker materials, and higher maintenance costs.

Who is Airo Shot Blast?

Airo Shot Blast is a leading manufacturer of blasting machines and equipment. Established with a vision to deliver high-quality, cost-effective solutions, the company is now recognized globally for its innovation and reliability.

They specialize in:

-

Portable shot blasting machines (P7 series: 150, 300, 500, 1000)

-

Cabinet type machines for small and medium parts

-

Hanger type machines for large workpieces

-

Tumble blasting machines for batch cleaning

-

Abrasives, spares, and safety gear

In short, if blasting is your need—Airo’s got the machine for it.

Absolutely. Unlike chemical cleaning methods that generate harmful waste, shot blasting is:

-

Dust controlled with modern dust collectors.

-

Recyclable: Abrasives can be reused multiple times.

-

Energy-efficient: Machines are designed to minimize power usage.

-

Cleaner process: No toxic by-products compared to chemical treatments.

So, if sustainability matters to your business (and it should), Airo’s machines tick the right boxes.

Can I Get Custom-Made Machines from Airo?

Yes, and that’s one of their strongest selling points. If your project requires a unique setup—say, an unusual workpiece size or automated conveyor system—Airo can design a tailored solution. This flexibility is a huge advantage over one-size-fits-all suppliers.

Let’s break it down:

-

Portable Shot Blasting Machines (P7 Series):

Compact, mobile, and versatile—ideal for on-site jobs like bridges, ships, and pipelines. -

Cabinet Type Blasting Machines:

Enclosed cabinets for precision cleaning of small components. Perfect for automotive workshops and tool industries. -

Hanger Type Blasting Machines:

Large, overhead machines designed for cleaning bulky items such as steel structures and castings. -

Tumble Blasting Machines:

Automated machines for mass finishing of small to medium-sized parts. -

Customized Solutions:

Tailor-made blasting setups for unique industrial requirements.

Why Choose Airo Shot Blast Equipments Over Competitors?

Great question! With so many brands on the market, what makes Airo stand out?

-

Durability: Machines are built with robust materials for long-lasting performance.

-

Cost-effectiveness: Competitive prices without compromising on quality.

-

Energy efficiency: Uses modern technology to reduce power and abrasive consumption.

-

Global trust: A growing client base across multiple industries worldwide.

-

After-sales support: Reliable customer service and spare part availability.

Safety’s no joke in the blasting world. Here are some golden rules:

-

Always wear personal protective equipment (PPE) such as helmets, gloves, and respirators.

-

Ensure proper ventilation in the blasting area.

-

Follow the machine’s operation manual religiously.

-

Never operate without checking hoses, valves, and nozzle assemblies.

-

Conduct regular maintenance and inspections.

Remember, safety doesn’t slow you down—it keeps your project running smoothly.

What Industries Use Airo Shot Blast Equipments?

You’ll find Airo machines in almost every industrial sector:

-

Automotive: Cleaning engine parts, body panels, and gears.

-

Shipbuilding: Removing old paint, rust, and scale from ship hulls.

-

Construction: Prepping beams, pipes, and rebars.

-

Aerospace: Surface finishing for durability and stress relief.

-

Railways: Refurbishing bogies, wheels, and large steel sections.

-

Foundries: Cleaning castings and molds.

Basically, if it’s metal or concrete, Airo’s equipment can handle it.

Not at all! Like any machine, shot blasting equipment requires regular care, but it’s not rocket science.

Here’s a simple checklist:

-

Daily: Check hoses, nozzle, and pressure regulator.

-

Weekly: Inspect filter bags and abrasive recycling system.

-

Monthly: Replace worn-out liners, seals, and valves.

-

Annually: Full service including calibration and replacement of critical spares.

Airo’s team also provides service manuals and technical support, so you’re never left scratching your head.

How Long Does a Shot Blasting Machine Last?

With proper care, an Airo machine can easily last 10–15 years. Of course, this depends on usage frequency, abrasive type, and operating environment. Heavy industries using machines 24/7 may need earlier overhauls, but the brand’s durability is well-known.

What Abrasives Can Be Used with Airo Machines?

Flexibility is key here. Airo machines work with a wide range of abrasives, including:

-

Steel shots (for heavy cleaning and peening)

-

Steel grits (for aggressive rust/paint removal)

-

Aluminum oxide (for delicate finishes)

-

Garnet and glass beads (for polishing and finer finishes)

-

Sand (in specific cases, though less eco-friendly)

Choosing the right abrasive depends on your application, surface type, and finish requirements.

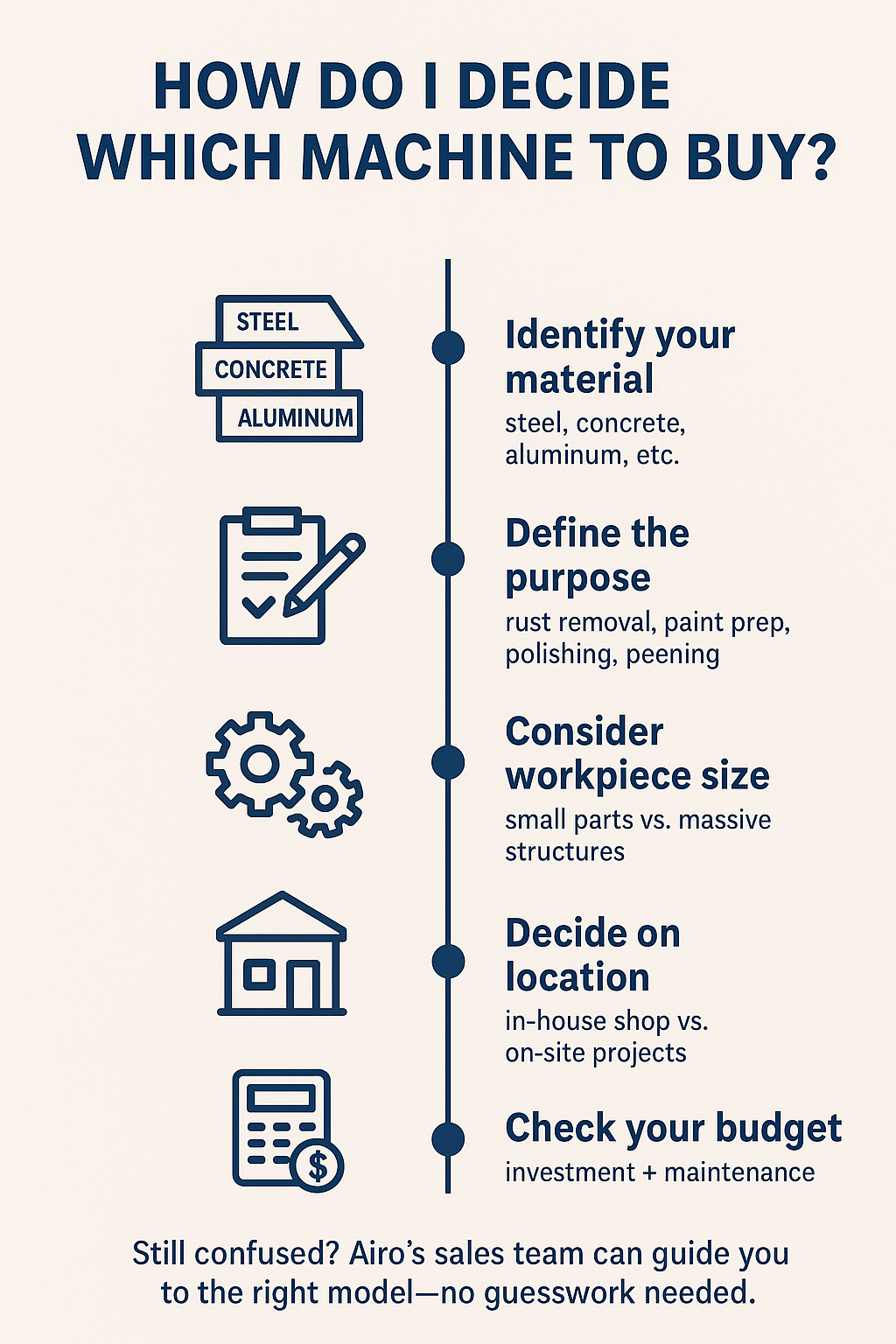

How Do I Decide Which Machine to Buy?