GET IN TOUCH

info@airoshotblast.in

Phone

+91-9119207701

Website

www.airoshotblast.in

Address

Jodhpur, Rajasthan, India

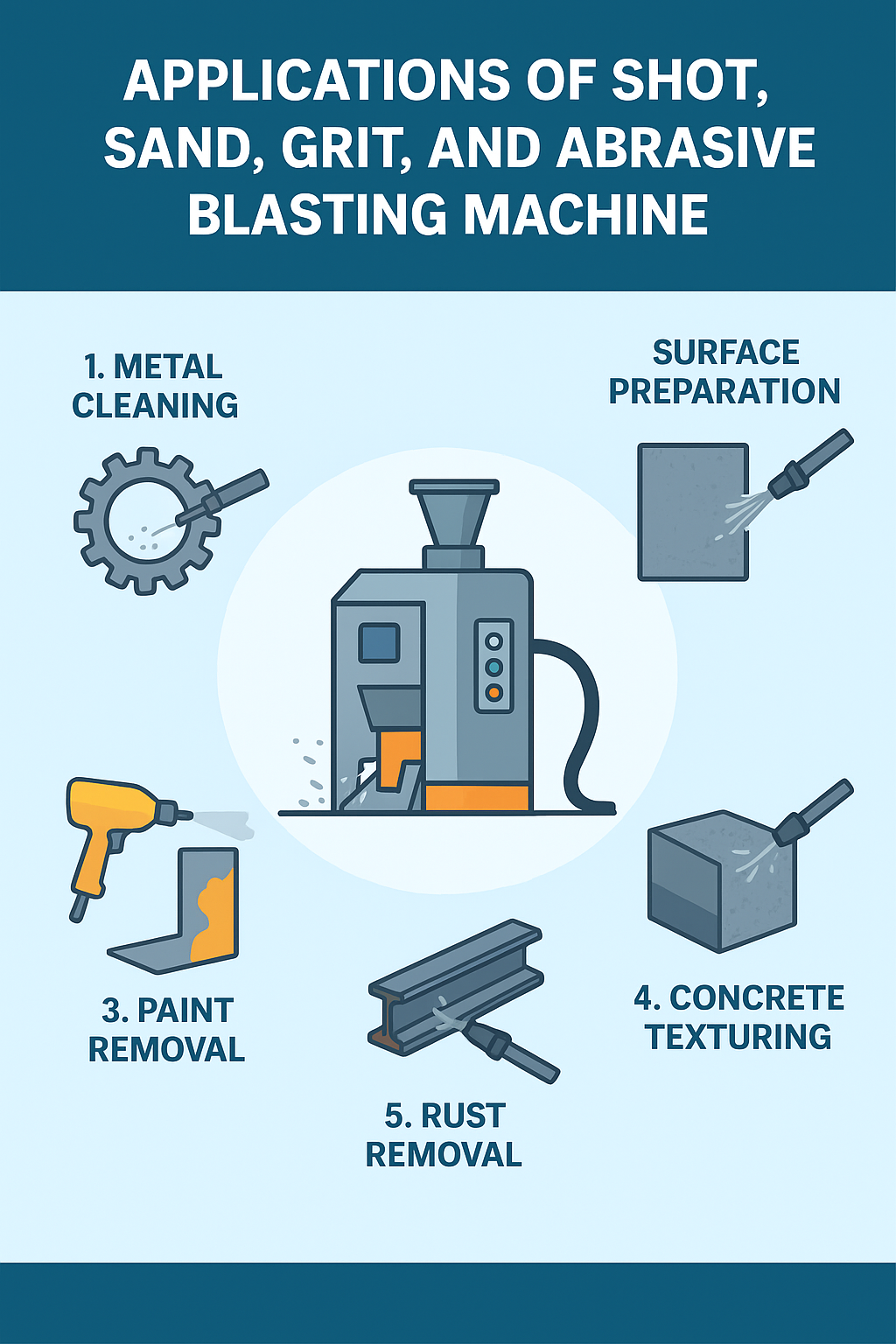

Applications of Shot, Sand, Grit, and Abrasive Blasting Machine

Ever wondered how industries keep massive metal structures rust-free, pipelines spotless, or old machinery looking brand-new? The secret lies in blasting machines—powerful tools that use shot, sand, grit, or other abrasives to clean, polish, or strengthen surfaces. Among the top innovators in this field, Airo Shot Blast stands tall, offering machines that cater to every surface treatment challenge.

This detail dives deep into the Applications Details - Airo Shot Blast; Shot, Sand, Grit, and Abrasive Blasting Machine, unraveling how they work, where they’re used, and why they’ve become indispensable in modern industries. Whether you’re in automotive, aerospace, shipbuilding, or heavy engineering, chances are you’ve already benefitted from this technology without even realizing it. So, let’s roll up our sleeves and get into the nitty-gritty!

Production 81%

Country Served 70%

On Time Deliver 99%

Customer Satisfaction 85%

Certified Engineers 95%

Why Choose Airo Shot Blast Machines?

You might be asking, “With so many blasting machine brands out there, why Airo Shot Blast?” Well, here’s why they’re leaders in the game:

-

1. Durability: Built with heavy-duty materials to withstand continuous use.

-

2. Efficiency: Saves time and labor compared to manual cleaning methods.

-

3. Versatility: Machines compatible with multiple abrasives.

-

4. Eco-Friendly Options: Reduced dust emissions and energy-efficient models.

-

5. Cost-Effective: Long service life reduces overall operational costs.